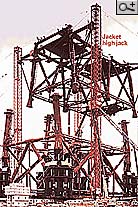

Raising of a steel jacket

Weight savings due to the vertical construction were calculated at somewhere between 500 and 600 tonnes. The cost of using our four 91 meter Push-Up masts was far less than that of the materials saved. Parts of the six-legged jacket were built in the UK and then transported to Norway for final assembly. Joining together the top and bottom sections was a complicated task: The 2700 tonnes top structure had to be raised 55 meters above the ground, while the bottom section was skidded in position under the suspended top structure, which was then lowered to prepare for welding the sections together at 28 points.

Some earlier lifts of this type have been high, and some have been heavier, but this is believed to be the highest and heaviest combination yet.